NDC International is proud to announce our relationship with Teikoku Taping System Co., Ltd (TTS). The company was founded in 1995 and is a wholly owned subsidiary of Nippon Kayaku Co., Ltd. TTS is committed to creating a better future and contributing to society with unique technologies and products. They strive to provide customers with the best products through creative innovation and by constantly challenging themselves to develop advanced technologies.

TTS – Leading Supplier for Dry Film Resist Applications

TTS specializes in the design, development and manufacture of semiconductor equipment used for taping, de-taping and handling of wafers and panel/substrates. They are the industry leader in dry film resist lamination, as well as the handling of thin wafers for back grind tape lamination, UV irradiation, removal and mounting to dicing tape on film frame.

TTS offers a comprehensive line of products and solutions. Their mid-end semiconductor manufacturing solutions include:

- Tape Laminator: Fully automatic tape lamination, cutting

- Automatic wafer transfer, alignment, tape lamination, cutting

- Offering two standalone solutions – one for 8-inch and one for 12-inch wafer size

- Blade cut or laser

- Recipe controlled heat options

- Tape Remover: Fully automatic tape remover

- Automatic wafer transfer, alignment, tape removing

- Offering two standalone solutions – one for 8-inch and one for 12-inch wafer size

- Adjustable removing speed

- Adjustable removing angle

- Thin wafer handling

- Inline UV Irradiation System

Their back-end solutions include:

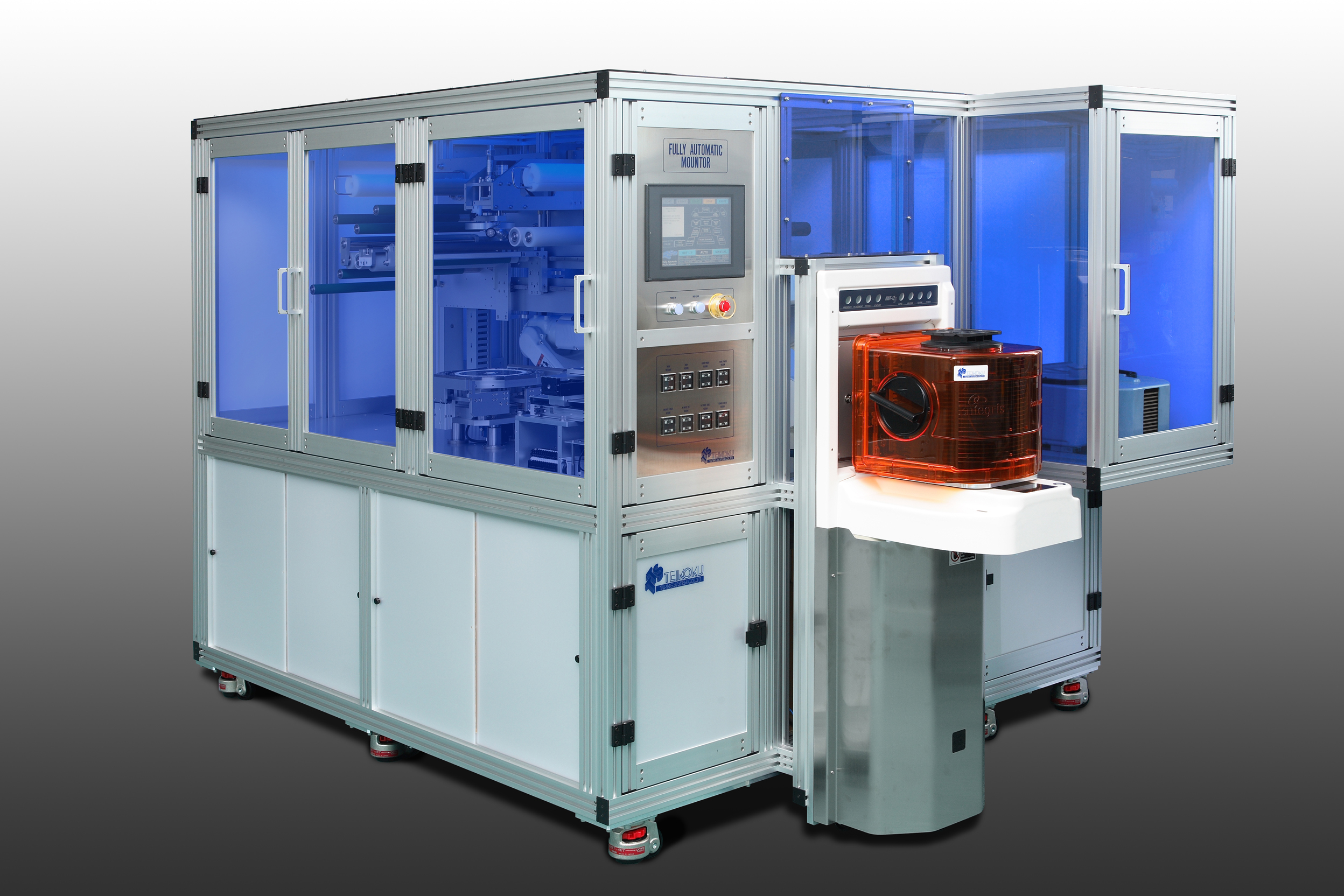

- Wafer Mounter: Fully automatic dicing tape wafer mounter

- Automatic wafer transfer, alignment, wafer mounting with dicing frame, removing protective tape

- Offering two standalone solutions – one for wafer sizes up to 12 inch and a multifunction option for 8 and 12-inch, or 6 and 8-inch wafer sizes

- Option for thin wafer handling special end effector

- Handles a range of thin, ultra-thin and warped wafers

- UV Irradiation: Fully automatic UV irradiation for UV dicing tape

- Automatic wafer transfer, UV irradiation for UV dicing tape

- Offering two standalone models – one for 8-inch and one for 12-inch wafer size

- Designed with simplicity in mind for greater MTBF and MTTR resulting in low cost of ownership

- UV intensity and exposure is controlled in real time

- Automatically adjusts the exposure to provide the proper exposure dosage limits

Now Offering Advanced Packaging Solutions

The various specialty tapes and films are facilitating many advanced packaging processes. TTS offers panel lamination and panel mounting to dicing tape systems. In addition, they now offer custom solutions per your requirements that integrate UV irradiation, de-bonding, detaping, and other functions.

Contact Don Johnson at (215) 355-2460 to learn more!

Customer support for demos, process development, field service are all based in the NDC International offices in Phoenix, AZ.

Read the full spec sheet here.