Neu Dynamics is proud to represent Korea Semiconductor System (KOSES) in North America. Founded in 1990, KOSES manufactures semiconductor backend equipment for display industries including FPD, Touch Panel, LED, Solar, PCB and general semiconductor industry.

KOSES is a leader in the global semiconductor market with a clear vision and challenging spirit. They leverage 3 decades of experience to rapidly innovate new technologies to address customer needs – delivering high quality and value.

At KOSES the Focus is on R&D

KOSES sees R&D as a core part of their mission. Their goal is to develop essential, emerging technologies to enhance competitiveness and grow their business. They focus on top talent and open innovation.

KOSES is committed to securing leading technologies through their sophisticated research and development process in which they predict customer needs, assess market viability, develop technology solutions and proactively test their production and performance. Customer value creation is at the heart of their process providing fast and accurate total solutions.

KOSES Systems: Value & High Quality

The core systems from KOSES include:

- Laser Marking

- Solder Ball Placement

- Pick and Place

KOSES Flipchip Laser Marking System

FEATURES

- Fully Universal Handler

- Laser Capable for Multiple Devices

- Full Auto Device Change

- Orientation & Quality Check Vision

Click here for the full spec sheet.

SOLDER BALL PLACEMENT SYSTEMS

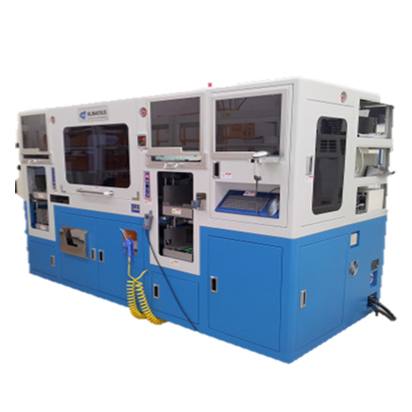

KOSES Flux Pre-Cleaning System KPM300

FEATURES

- Multiple Function System for Cleaning: OSP Pre-Cleaning & Via Cleaning

- Flux Dotting for OSP Removal on Bottom Ball Pad

- Strip Warpage Compensation

- Reliable Flux Auto Supply & Management

Click here for the full spec sheet.

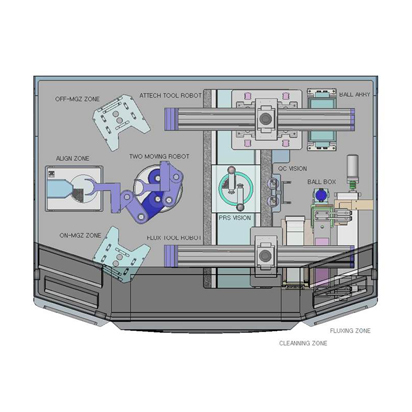

KOSES KAM7000F Solder Ball Attach System

FEATURES

- New Solder Ball Mounting System for Singulated Packages Handles Wide Boat Flux Dotting & Ball Attach in 1 Shot

- Cycle Time for 1 Boat Under 29 Sec.

- Applicable Min Ball Diameter: 0.2mm, Min Pitch: 0.4mm

- Vision Inspection is Optional for the Offloader (Model: KUM4000F)

Click here for the full spec sheet.

KOSES KWA 970 Wafer Solder Ball Attach System

FEATURES

- Interchangeable Loader/Off Loader According to User Selection

- 6 ~ 8-inch Wafer Application

- Robot System Handles Wafers at 8 Points in 340 Degrees

- Optional Pre-Alignment System

- Transfer Arm with Sensor to Identify the Wafer

- X, Y, θ Table Controlled by PRS Vision System

- Flux Mask Printing System Ensures the Exact Flux Volume and Flux Position

- Individual Vacuum Control System Allows Ball Placement on the Wafer Edge Corner

- Pre-Vision and Post Vision to Verify Accuracy

Click here for the full spec sheet.

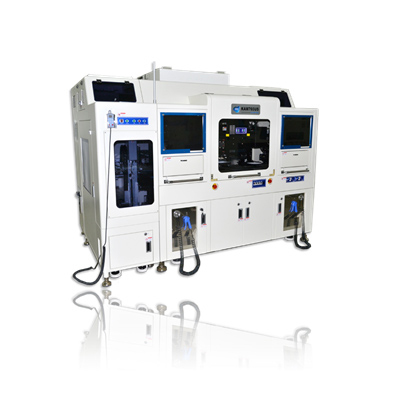

Pick & Place System

FEATURES

- Two Models: KPUM3000 (Boat to Tray) and KPP400 (Tray to Boat)

- Quick Conversion (less than 5 min.)

- Laser Height Sensor

- Boat Size:

- 6mm X 135.9mm

- 6mm X 160mm

- Tray Type: JEDEC, EIAJ, TOSHIBA, ELPIDA

- Package Size: Min. 6×6 ~ Max. 15×15

Click here for the full spec sheet.

We are truly excited about our partnership with KOSES and look forward to discussing their system benefits with you.