Neu Dynamics is proud to represent budatec GmbH in the USA. We know you will be as excited as we are about their innovative vacuum soldering systems – the most powerful and smallest on the market today. In fact, they have 80% world market share and are well regarded as a technology leader. Their systems are used across the globe in the production of electronic and power electronic components, by automotive industry suppliers, in the manufacturing of lasers and in medical technology. In addition, they are used in numerous R&D faciltites as the foundation for the realization of new technologies.

If you have any questions about these systems, or would like to talk about how they can bring more flexibility and accuracy to your manufacturing processes, please stop by Booth #613 at IMAPS 2025. We look forward to meeting you!

Vacuum Soldering Technology: The Benefits

Vacuum soldering is a form of convection soldering that produces a superior joint. Vacuum soldering eliminates voids and pores that can occur when flux and solvents escape from the soldered joint but cannot totally exit. With the help of the vacuum, these residues can escape in the preheating phase so that in the liquidus phase of the process, they produce few/no defects in the soldered joint.

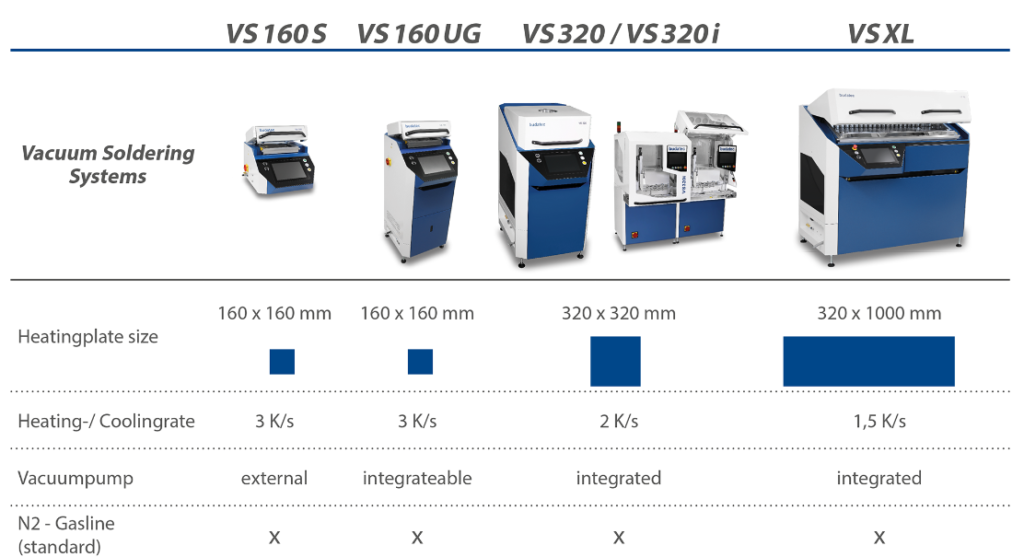

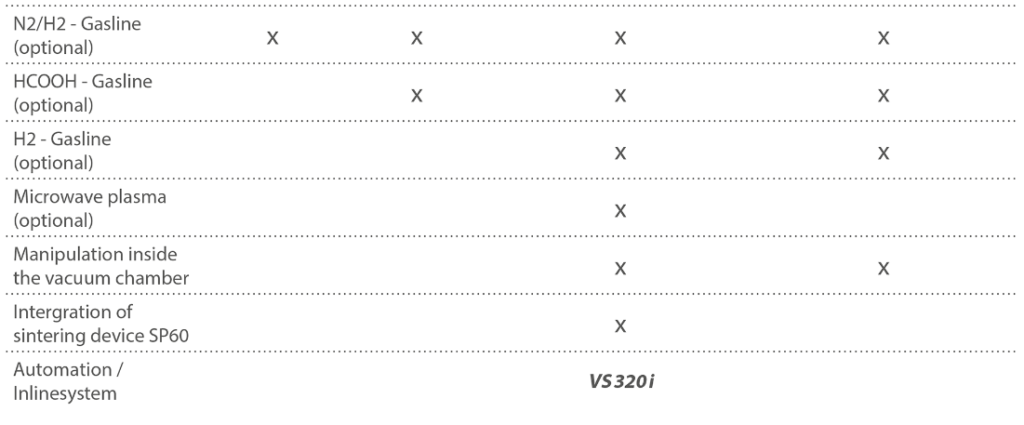

Budatec Has the Vacuum Soldering System to Meet Your Needs

Regardless of your manufacturing needs, budatec offers a system for you. From small, medium and large batch to fully-automated production systems, budatec has a solution that will increase your yield and deliver terrific flexibility, expandability and ease of integration.

The VS line consists of 4 base machines and offers the ability to integrate the budatec sintering press.

VS 160 S & VS 160 UG – R&D & Small Batch

VS 160 S & VS 160 UG – R&D & Small Batch

This system offers the highest performance with a small footprint, due to its high heating and cooling rates (approximately 200 K/min). It is available as a VS 160 S (benchtop) and as a VS 160 UG (with a base frame). This makes it possible to integrate additional options such as a vacuum pump or HCOOH gas line.

This system offers the highest performance with a small footprint, due to its high heating and cooling rates (approximately 200 K/min). It is available as a VS 160 S (benchtop) and as a VS 160 UG (with a base frame). This makes it possible to integrate additional options such as a vacuum pump or HCOOH gas line.

VS 320 – R&D & Medium/Large Batch

The VS 320 is frequently used in R&D and is a great choice for medium and large batches due to the heating plate size (320 mm x 320 mm) and the high achievable performance. Several options are available including hydrogen (concentration adjustable up to 100%), HCOOH, special gases, microwave plasma and the integration of the budatec sintering press.

The VS 320 is frequently used in R&D and is a great choice for medium and large batches due to the heating plate size (320 mm x 320 mm) and the high achievable performance. Several options are available including hydrogen (concentration adjustable up to 100%), HCOOH, special gases, microwave plasma and the integration of the budatec sintering press.

VS 320 I – Large Batch

This system offers autonomous loading and unloading of product carriers. It is based on the VS 320 with all available options. It is an automatic inline vacuum brazing system that is flexible and simple to expand. Several technology steps can be integrated inline quickly and easily.

This system offers autonomous loading and unloading of product carriers. It is based on the VS 320 with all available options. It is an automatic inline vacuum brazing system that is flexible and simple to expand. Several technology steps can be integrated inline quickly and easily.

VS XL – Large Batch

This system can be used for processing large parts and large batches due to the heating plate size of 1000 mm x 320 mm. Available options include hydrogen (concentration adjustable up to 100%), HCOOH and special gases as well as motor-driven manipulators integrated within the workspace.

This system can be used for processing large parts and large batches due to the heating plate size of 1000 mm x 320 mm. Available options include hydrogen (concentration adjustable up to 100%), HCOOH and special gases as well as motor-driven manipulators integrated within the workspace.

Stop By Booth #613 at IMAPS to Learn More

We look forward to sharing more information with you about these powerful systems at IMAPS 2025 in Phoenix from March 3rd to 6th.

Reach out to Josh Markle at 919-208-1788 for more details!