Our partner Boschman has long led the way in sintering technology and continues to be a supplier of top choice whether you engage in small batch or large-scale production. We are pleased to feature the new launch of their innovative Sinterstar Mini. This system is unique, versatile and ideal for R&D and prototyping. It offers a very compact design, quick and easy changeover and handles a wide variety of products.

Introducing the Sinterstar Mini

The Sinterstar Mini was designed for universities, laboratories, R&D departments and SME companies. It is extraordinarily easily to use – ready for operation in 45 minutes! It offers fast change-over, tons of flexibility and is a practical solution when you need to sinter a wide variety of products.

Specifications:

- Effective sinter area: 66x66mm

- Effective product area: 100x100mm

- Product thickness range: 0,1-70mm

- Sinter temperature up to: 280⁰C

- Insert force range: 30N – 78kN

- Programmable sinter pressure, time and temperature

- Universal Base Tool set for one dynamic insert

- Color touchscreen / HMI

- Advanced and precise process control with data export functionality

- Micro controlled environment

- Vacuum controlled environment (optional)

- Easy product loading by means of a drawer at the frontside

Boschman’s Sinterstar Mini is an affordable, entry system for silver sintering designed for small sintering trials. In addition the system sinters an impressive range of products including Die-to-Substrate, Die-to-Leadframe, Clips, Preforms and Package-to-Heatsink attach applications.

Sinterstar Mini Leverages Dynamic Insert Technology

Boschman’s patented Dynamic Insert Technology provides maximum control and guarantees a uniform pressure. This allows you to easily vary pressure via HMI settings. The system offers closed loop pressure control meaning the insert pressure follows the programmed pressure. Plus the Sinterstar Mini’s Universal Base Tool contains one dynamic insert and requires minimal maintenance.

“Secret Sauce” Makes Prototyping a Breeze

The system’s Universal Base Tool set is a powerful feature that makes research and quick prototyping a breeze! Pop in your dedicated inserts and alignment plates and you are ready to produce a unique product quickly and easily. It’s fast, easy and flexible.

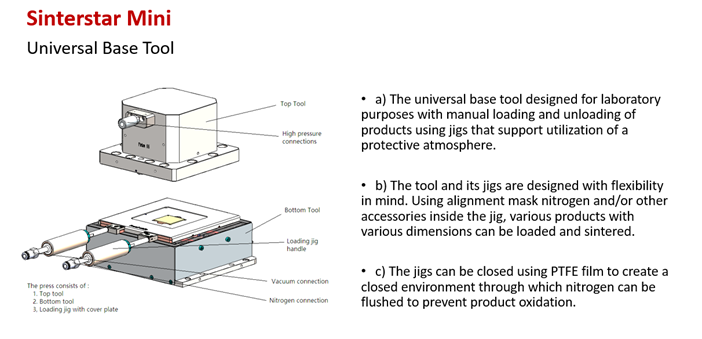

The Universal Base Tool consists of:

- Base top tool for 1 dynamic insert in a slide

- Base bottom tool including loading jig with N2 supply

- Product height conversion set from 0,01-70 mm

- 1x film roll, 50um thickness, 160 mm width, 100m length

Dynamic Insert Units are available separately and include the standard 66x66mm and a 22x22mm option. Pistons are also available in the following options: 55mm (standard), 100mm, 25mm, 7.5mm.

Download a Power Point with full system specifications, click here.

Reach out to Kevin Hartsoe – 215-355-2460 – to discuss putting the Sinterstar Mini to work for you!