MicroAssembly Technologies, Ltd. (MAT) was founded in 2000. With 35 years of experience, the folks at MAT deliver simple, flexible, high-value solutions for die attach. Because they focus exclusively on die attach technologies, they are at the top of that game offering machines with unmatched versatility and lowest cost of ownership.

NDC represents MicroAssembly Technologies, Ltd. (MAT) in the USA, Canada and Mexico.

MAT Die Attach – Simple is Better

MAT provides simple but powerful solutions for your complex die attach and dispensing applications. If your processes involve complex, high-value applications such as Multi Chip Modules, Imaging Devices, Sensors, MEMS, Flip Chip Modules, etc. you will definitely want to learn more about their proven systems.

Currently they offer two models:

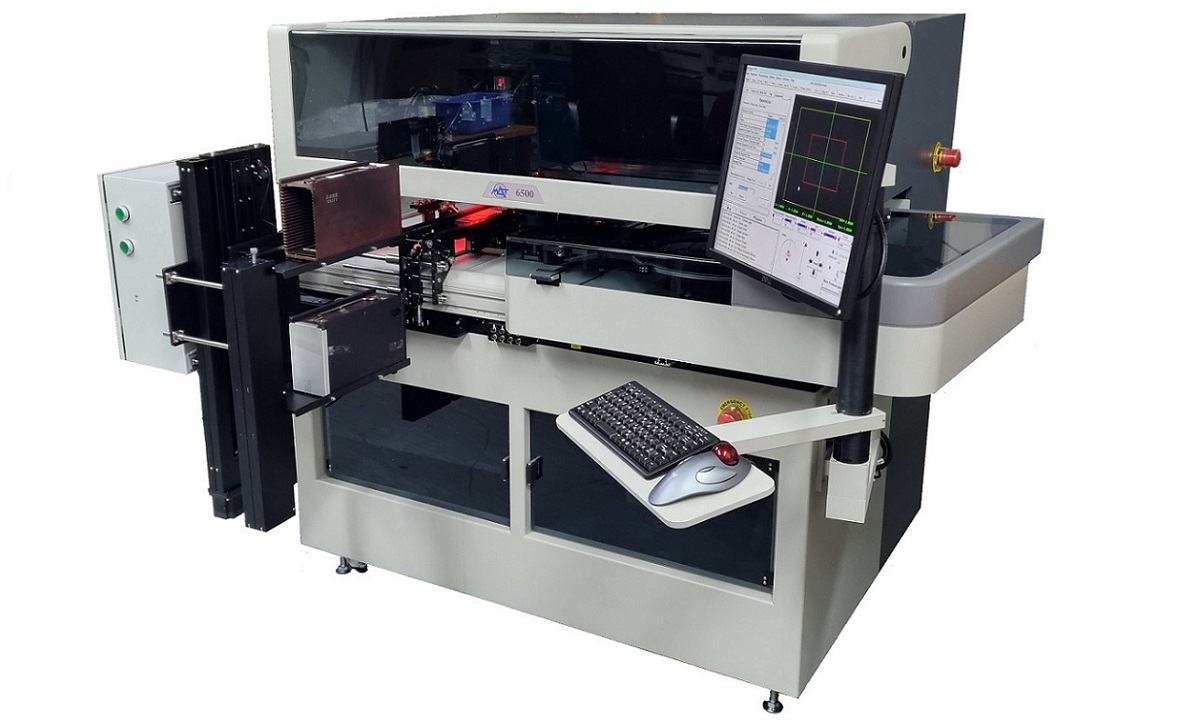

- High Accuracy Model 6500 Die Attach System

- Model 6200 Table-Top Automatic Die Attach System

These two systems share the same base machine which allows you to transfer recipes between them. Capability for all known die attach processes is already implemented into the base machine. Plus, their systems are incredibly versatile with hardware add-ons that make expanding capabilities in the future simple.

In fact, MAT’s systems offer you three main advantages:

- First, there is no competition at this price point.

- Second, the machines are extremely easy to program and customers say that switching processes takes only minutes or seconds!

- And finally, the machines have an open design which makes them incredibly flexible.

The die attach systems from MAT can handle everything you throw at them with high accuracy and high yield. In addition, the company continues to develop new features and capabilities to address the changing needs of customers and the die attach process.

MAT Die Attach Systems

The 6500 Model is a floor model that can handle wafers. The 6200 is a table-top model that handles die from carrier trays and waffle packs.

MAT Model 6500 Die Attach System – Automatic, High Accuracy

This system performs Face Up and Flip Chip applications based on Epoxy, Eutectic, C2/C4, Ultrasonic, ACF/ACP, Silver Glass, UV Adhesives, Ag Sintering, etc. All process capabilities are built-in and easily switched from one to another by enabling/disabling a parameter.

- Switch processes in seconds with the versatile, user-friendly graphic interface

- All hardware is plug and play

- Fully automatic system with a large work area

- Optional manual material load/unload for ease of operation

- For Multi-Chip Modules, RF, Hybrid applications the machine handles components as small as 150 μm, up to practically any size presented in various forms

- The very high placement accuracy ensured by the servo motion systems for the main axes, plus high-resolution digital vision allows the system to be used for applications requiring up to 3 μm accuracy

To download the full brochure, click here.

MAT Model 6200 Automatic Die Attach System – The Crossover

This automatic die attach system utilizes a small and unique table-top configuration. It offers unrivaled versatility – allowing you to perform the widest range of cold and heated die attach processes on the same machine. Process capabilities include Epoxy Die Attach, different Eutectic processes, GGI based on Ultrasonic or Thermo-compression processes, ACF/ACP, Ag Sintering, Die Stacking and many other processes.

- Fully-automatic and Semi-automatic process allowing greatest flexibility and easy of operation

- Handles active and passive components presented in 2″ and/or 4″ waffle/gel packs, different size tape and reel feeders and custom trays

- Very high accuracy servo systems control the main machine axes

- High resolution digital vision and advanced image processing system

- Time-pressure, volumetric or jet dispenser for applying thermal or UV curing adhesives

- Double dispenser for two different adhesives

To download the full brochure, click here.

MAT’s die attach systems deliver next level value and flexibility. Give us a call to discuss how to put their systems to work for you.