At the iMAPS show in Boston earlier this month, we had huge interest in budatec’s systems from power module manufacturers. Their systems are the new gold standard, having won 80% of worldwide market share. Budatec has 30 years of experience and offers vacuum soldering and sintering systems ranging from small R&D to fully automated systems. The company serves the semiconductor, photovoltaic, automotive and medical industries worldwide.

Expandable Vacuum Soldering Systems

Vacuum soldering systems produce flawless joints versus traditional solder connections. With the help of the vacuum, residues can escape in preheating dramatically reducing defects. Budatec’s VS Line includes a range of systems to increase your yield that offer incredible flexibility, expandability and ease of integration. From small, medium and large batch to fully-automated production systems, budatec has a system for you. The VS line consists of 4 base machines and offers the ability to integrate the budatec sintering press.

For R&D – Small Batch

VS 160 S & VS 160 UG: Offer highest performance with a small footprint due to high heating and cooling rates (approximately 200 K/min).

- The machine is available as a VS 160 S (benchtop) and as a VS 160 UG (with a base frame). This makes it possible to integrate additional options such as a vacuum pump or HCOOH gas line.

- VS 160 S Spec Sheet

- VS 160 UG Spec Sheet

For R&D – Medium & Large Batch

VS 320: Offers high achievable performance. Features options such as hydrogen (concentration adjustable up to 100%), HCOOH, special gases, microwave plasma and the integration of the budatec sintering press.

For Large Batch

VS 320 i: Offers autonomous loading and unloading of product carriers. Based on the VS 320 with all available options. Fully automatic inline vacuum brazing system that is flexible and simple to expand. Several technology steps can be integrated inline quickly and easily.

VS XL: For processing large parts and large batches. In addition to the available options hydrogen (concentration adjustable up to 100%), HCOOH and special gases as well as motor-driven manipulators can be integrated within the workspace.

Sintering Presses Amplify Your Possibilities

Budatec’s offers two sintering machines. The SP 60 integrates into the VS 320 vacuum soldering system to seamlessly add sintering capability. The SP 300 is a stand-alone sinter press that is ideal for cleanroom applications. Sintering is an innovative technology used to create more powerful and reliable power modules. In this joining method, microscale sintered particles and solvents are used to form a sintering paste that is then printed or dispersed onto the substrate. A bond is formed between the parts by using temperature (low temperature range 200 °C to 260 °C), time and pressure.

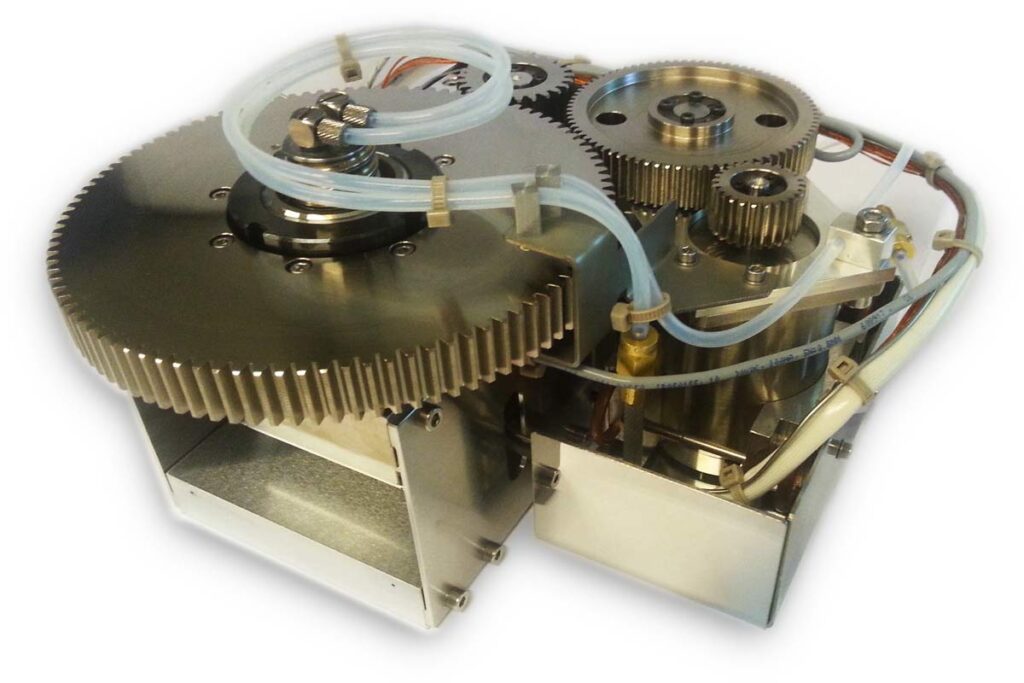

SP 60 Sintering Press

The SP 60 expands the VS 320 vacuum brazing system into a sinter press. It produces sintered connections under inert or reduced atmospheres and provides significant improvement in the connection in terms of reliability and strength (multiplication of the shearing forces).

The SP 60 expands the VS 320 vacuum brazing system into a sinter press. It produces sintered connections under inert or reduced atmospheres and provides significant improvement in the connection in terms of reliability and strength (multiplication of the shearing forces).

Features:

- Area: up to 60 mm x 60 mm

- Adjustable Force: up to 15 kN

SP 300 Sintering Press

The SP 300 is a fully automatic sintering press that produces connections under inert and reduced atmospheres. It uses both a servo-electric drive and a load cell so that the programmed force is set very quickly and very precisely. There are no hydraulic components, eliminating the risk of uncontrolled oil leakage in the production area.

The SP 300 is a fully automatic sintering press that produces connections under inert and reduced atmospheres. It uses both a servo-electric drive and a load cell so that the programmed force is set very quickly and very precisely. There are no hydraulic components, eliminating the risk of uncontrolled oil leakage in the production area.

Features:

- Ideal for cleanroom requirements

- Area: 180 x 225 mm2

- Height Between Punch Plates: 75 mm

- Pressing Force: 0,5 – 300 kN

We think you will be as excited as we are about these powerful systems from budatec. Please reach out if we can answer any questions about these systems and how they can bring more flexibility and accuracy to your manufacturing processes.