Leading the Way in Trim & Form Systems for Power Modules

In June of 2024, Trim Form Automation (TFA) Europe and Include Industries launched a new semiconductor back-end equipment company called Powertrim Technologies. The company grew out of Tooling Specialist Derksen (TSD) – a respected supplier of precision mechanical parts and tools with over 20 years of experience in the design and manufacture of trim and form tools. TSD successfully developed several prototype and production trim and form tools for power modules.

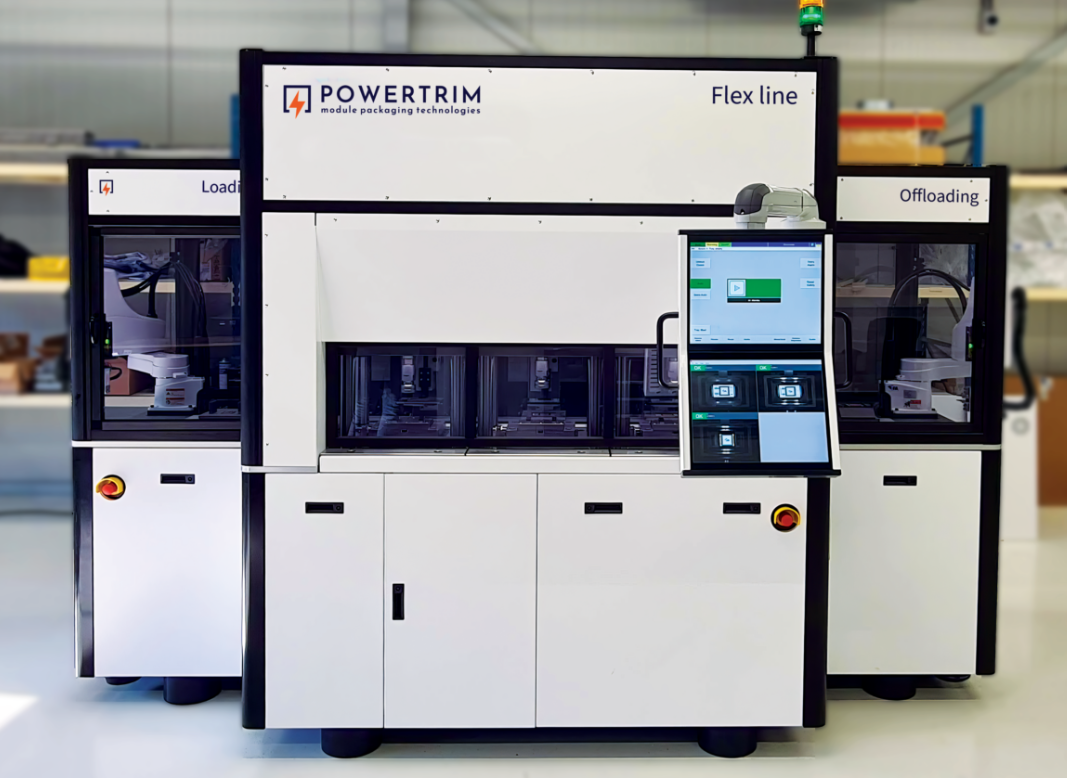

Later as TFA Europe, they launched their Flex Line to address the need for automation, innovative product handling and inspection, including additional processes like optical inspections and laser marking. Now the Flex Line has been rebranded under the Powertrim name.

Meet Powertrim at The Battery Show

Powertrim’s goal is to be the world’s #1 OEM of high-performance handling, assembly and testing machines for automated power electronics. NDC is pleased to represent Powertrim in North America and to feature the Powertrim Flex Line in our booth at The Battery Show in Detroit, MI. We hope you will stop by to learn more on October 8th – 10th. Booth #2550.

Ultimate Flexibility & Ease

The Powertrim Flex Line is an integrated trim and form manufacturing solution for power modules and related processes. This robust, modular system is designed for ultimate flexibility with regard to handling, press force and package shape. It offers incredible ease of use – including product changeovers within 15 minutes! Other notable features:

- Press Force Up to 100kN

- Number of Press Modules is Configurable

- Speed: 400 to 1200 Power Modules per Hour (depending on process steps/options)

- Loading and Offloading Options: Magazines, Trays, In-Line, AGV’s, SMEMA Compatible

- Optional Modular Integrations: Barcode/DMC Reader, Laser Marking, Laser Deflashing, Product Inspection, MES Integration