NDC International representing budatec GmbH in North America.

Budatec is based in Berlin, Germany and specializes in developing equipment for the semiconductor and photovoltaics industries. They are a technological leader in this segment specializing in the use of hydrogen and plasma gases. Their customers include top technology companies, R&D departments of well-known institutes and universities.

Budatec’s Innovative Vacuum Soldering Systems Increase Your Production

Budatec has more than 20 years of experience in developing vacuum soldering technologies ranging from small R&D furnaces to fully automated soldering systems. They offer four innovative vacuum soldering systems that can support a significant increase in your production. The benefits of vacuum soldering are many, including little to no residual contamination on the product, no degassing processes on the product and assembly in high vacuum.

In addition, vacuum soldering provides:

• Integrated (or separate implementation of) cleaning and scaling processes

• Different pressure areas can be created inside the sealed chambers

• Bonding surfaces free of oxides and cavities, ranging from chip to ceramic substrate

• Sealing of chambers with a previously defined gas atmosphere

• Integration of drying and degassing processes

• Possibility of a further miniaturization

• Better derivation of heat loss

Budatec’s line includes 4 units that offer the smallest and most powerful vacuum soldering systems available today! They include the:

1. VS160S: table-top model, ideal for low volume production

2. VS160UG: stand-alone production model

3. VS320: stand-alone model with integrated plasma cleaning capability

4. VS-XL

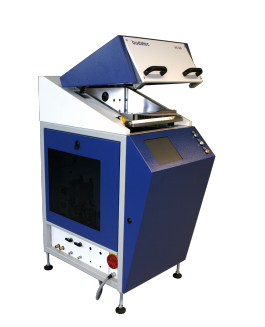

Budatec’s VS320 Vacuum Soldering System

We think you will be especially excited about the VS320 system which is a stand-alone model with integrated plasma cleaning capability. This system can handle soldering processes up to 450 degrees Celsius with and without flux. In addition, all of the standardly used vacuum brazing technology gases can be employed including nitrogen, hydrogen and forming gases. The VS320 system offers impressive heating and cooling rates and short suction and rinsing times, that result in short process times – from 6 minutes! You will also benefit from integrated cleaning cycles that utilize formic acid, hydrogen reduction and plasma.

The system specifications include:

• Plate Size: 320mm x 320mm

• Max Substrate Height: 100mm

• Max Solder Temperature: 450 degrees C

• Heat Up/Cool Down: Max. 2.5K/s

• Possible Process Gases: N2; N2H2 95/5% H2 bis 100%

• Max. Load: 15kg

For a full spec sheet click here.

To see a VS320 video, click here.

Learn More About budatec’s Systems

Contact Kevin Hartsoe at (215) 355-2460 to learn more about how the VS320 or budatec’s other vacuum soldering systems can improve your production!